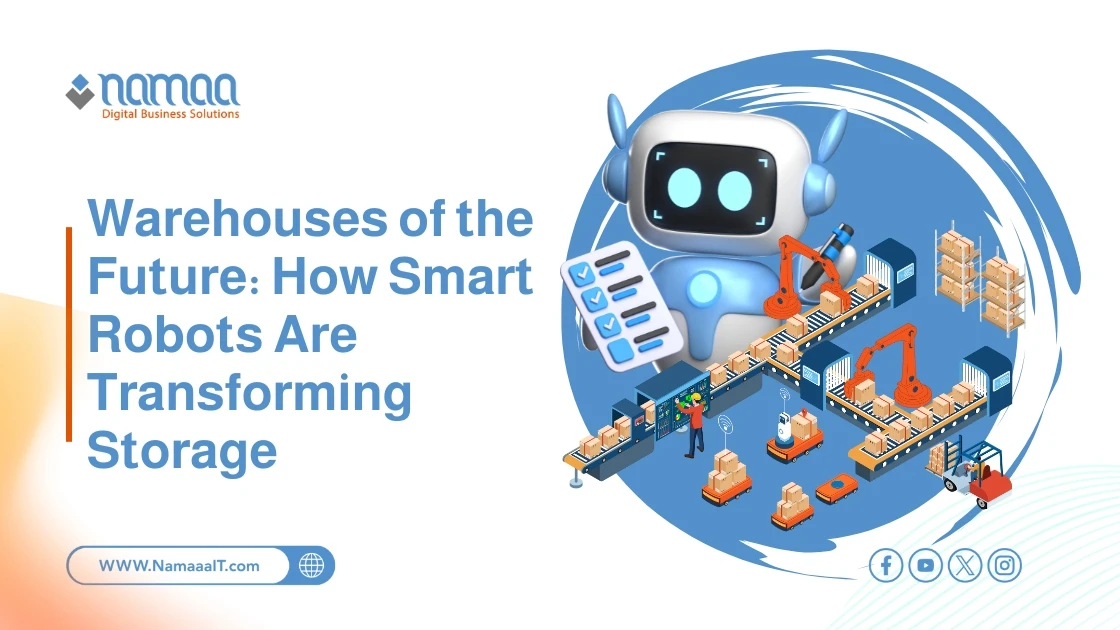

A New Era for Warehouses: The Rise of Robotics

Warehouses today are undergoing a technological revolution driven by the increasing reliance on robotics. Traditional storage facilities can no longer keep pace with the massive demand for fast delivery and highly efficient inventory management without smart automation. Robots now handle loading, sorting, and inventory tasks with greater accuracy and speed than humans—reducing errors and enhancing operational capacity. Companies investing in this technology are enjoying lower costs and greater adaptability in rapidly changing markets. With ongoing advancements in AI, warehouses are evolving into intelligent logistics centers where robots operate with seamless coordination and precision.

What Are Warehouse Robots and How Do They Work?

Warehouse robots are intelligent machines programmed to perform storage, transport, and sorting tasks with minimal human intervention. They rely on precise sensors and autonomous navigation technologies such as LiDAR and 3D cameras to map locations and avoid obstacles. Integrated with Warehouse Management Systems (WMS), these robots execute commands efficiently. Here's how the process works:

Receiving: Robots unload goods from trucks or production lines.

Sorting: They place items in their designated storage areas.

Inventory: Scanning technologies update inventory databases in real time.

Fulfillment: Robots transport orders to packing and shipping areas swiftly.

Their strength lies in near-continuous operation, minimizing downtime and human fatigue. Tasks can be reprogrammed easily to meet changing demands. This synergy between hardware and software allows warehouses to handle high-volume workflows with unmatched flexibility.

Types of Warehouse Robots and Their Roles

Technological advancements have led to a wide variety of warehouse robots designed for different functions. Below are the most common types:

| Robot Type | Primary Function | Notable Examples |

|---|---|---|

| Autonomous Mobile Robots (AMRs) | Self-navigation and material transport | Kiva Robots |

| Picking Robots | Item picking and order preparation | RightHand Robotics |

| Fixed Robots | Automated packaging and assembly | ABB IRB Series |

| Drones | Inventory scanning and high-rack monitoring | PINC Air Drones |

| Robotic Arms | Handling heavy loads and bulky materials | Fanuc Robotic Arms |

Each type performs specific tasks more efficiently than traditional solutions. For instance, AMRs significantly reduce time spent moving items between zones, while drones simplify stocktaking in large warehouses with instant inventory insights. A combination of these technologies maximizes automation and operational output while keeping costs in check.

How Robots Enhance Inventory Management Efficiency

Inventory management has long been a complex challenge—but robots have introduced revolutionary solutions:

Real-Time Inventory Updates: Equipped with sensors and scanners, robots constantly update stock data without manual audits.

Waste Reduction: Accurate tracking enables immediate detection of overstocking or shortages.

Smarter Space Management: Robots optimize storage placement to make the best use of every square meter.

Adaptability: During demand spikes, robots reorganize workflows automatically.

24/7 Operation: No breaks or holidays—robots keep working non-stop.

These benefits make robots indispensable for businesses aiming to improve inventory control while cutting costs and maintaining delivery speed.

Will Robots Replace Human Workers?

A common concern: will robots eliminate human jobs? The reality is that warehouse robots aren’t here to replace humans, but to change their roles. Robots handle tedious, dangerous, or physically demanding tasks, while workers shift toward more strategic and supervisory responsibilities.

Benefits of a human-robot collaboration include:

Reduced physical strain and workplace injuries.

Opportunities to learn new skills in robotics management.

Lower fatigue from repetitive tasks.

New employment opportunities in maintenance, programming, and data analysis.

Transitioning to an automated warehouse requires staff training, but creates new roles while redefining traditional ones. Industry leaders view human-robot synergy as the ideal path to productivity and workplace safety.

Robots and Faster Shipping Times

In the fast-paced world of e-commerce, shipping speed is a critical competitive factor—and robots are a game-changer in this domain.

Impacts on delivery speed:

Faster Picking: Picking robots prepare orders quicker than manual labor.

Automated Packing: Robotic arms handle packaging efficiently.

Smart Scheduling: Task distribution is optimized through AI-driven systems.

Same-Day Shipping: Realistic and cost-effective thanks to robotic speed and precision.

Reduced Errors: Speed doesn’t come at the cost of quality—automation reduces shipping mistakes.

These advantages improve customer satisfaction and help businesses meet rising consumer expectations.

Tips for Small Businesses Adopting Warehouse Robots

Many small businesses assume automation is too expensive, but warehouse robotics have become more flexible and scalable than ever. Here’s how SMEs can start smartly:

Start Small: No need to overhaul everything—test one or two robots on repetitive tasks.

Prioritize Tasks: Focus on high-labor processes like item transfers or routine stock checks.

Choose a Reliable Vendor: Partner with providers offering scalable solutions and support.

Train Your Team: Skilled staff can maximize robotic efficiency and minimize errors.

Track Performance: Use analytics to assess ROI and adjust deployment strategies.

When implemented wisely, automation is not a luxury—it’s a necessity for reducing costs, improving supply chains, and competing in saturated markets.

Future Outlook: Where Are Logistics Robots Headed?

Warehouse robotics are advancing rapidly, fueled by AI and global supply chain demands. Here's what the future holds:

| Trend | Explanation | Impact |

|---|---|---|

| Collaborative Robots (Cobots) | Work safely alongside humans | Boosts safety and task flexibility |

| Predictive AI | Smart demand forecasting and task optimization | Reduces excess inventory, enhances accuracy |

| Cloud Robotics | Remote control and updates via the cloud | Cuts maintenance costs, supports scalability |

| Increased Drone Usage | Expanded inventory and delivery roles for drones | Speeds delivery, reduces manual labor |

| Multi-Function Robots | Robots capable of performing diverse tasks | Lowers investment in multiple robot types |

Warehouses are poised to become smarter and more efficient than ever. Companies embracing these trends will lead in cost-efficiency, customer satisfaction, and competitive advantage.

FAQs

1. Do warehouse robots need regular maintenance?

Yes, regular upkeep includes battery checks, software updates, and sensor calibration to ensure optimal performance and avoid unexpected failures.

2. How do robots affect warehouse energy consumption?

While robots consume electricity, their operational efficiency offsets energy use. Smart charging systems also help minimize energy consumption.

3. Can robots be customized for different types of goods?

Absolutely. Robots can be programmed and outfitted with specialized attachments to safely handle items of varying size and weight.

4. What are the risks of using robots in storage environments?

Potential risks include system malfunctions or collisions. However, advanced safety systems minimize these risks significantly.

5. Are warehouse robots affected by environmental conditions?

Warehouses are usually controlled environments, but robots used in exposed areas should be weather-resistant to heat or humidity to protect internal components.

Summary:

✅ 80% of major e-commerce companies now use warehouse robots, cutting operational costs by up to 30%.

✅ Mobile robots reduce transport time within warehouses by up to 50% compared to manual processes.

✅ Robots achieve 99.9% inventory accuracy, reducing supply chain errors and unexpected losses.

✅ The global logistics robot market is projected to reach $27 billion by 2027, growing at an annual rate of 15%.

✅ Shipping speed increases by up to 60% with robots, making same-day delivery a viable and cost-efficient reality.

.webp)